The history of Miele from 1899 until today

-

1899-1909

-

1899

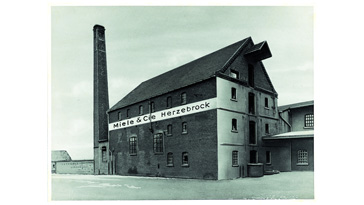

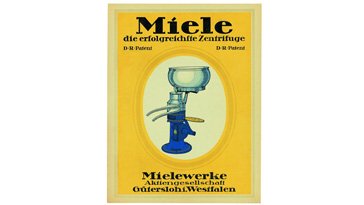

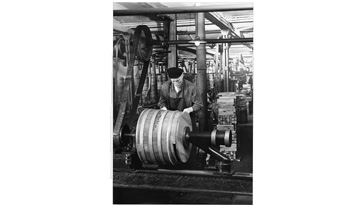

Carl Miele (left) and Reinhard Zinkann sign a contract in June 1899 with the aim of establishing Miele & Cie., a factory for making cream separators by 1 July 1899.

The young company, housed in an old saw and corn mill in the community of Herzebrock near Gütersloh, starts manufacturing cream separators, with a workforce of eleven employees.

-

1900

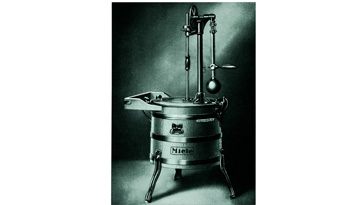

The Meteor butter churn is added to the range in the second year and reduces the workload on farms, particularly on farmers' wives.

-

1903

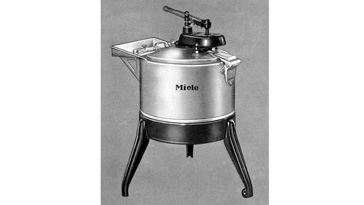

The Model A washing machine with a lid-mounted agitator facilitates operation quite significantly. The agitator has a flyweight which perpetuates motion and is much easier to move than a simple lever.

-

-

1910s

-

1910

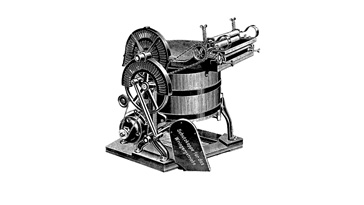

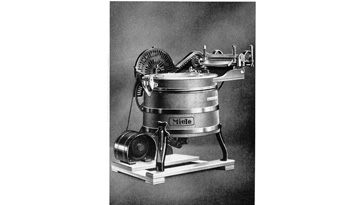

Miele's first washing machine with its own electric motor goes on sale in 1910. The same motor also powers the wringer. A release lever allows the wringer to be disengaged from the drive mechanism.

-

1912

Encouraged by their huge successes thus far, the founding fathers venture into the production of motorcars. Between 1912 and 1914, a total of 143 cars are delivered at prices between 5,100 and 7,900 marks. Due to the extensive capital investment required by this line of business it is soon abandoned again.

-

1914

Miele introduces its first water-powered washing machine (No. 40) even before the first world war. At that time, water was considerably cheaper than electricity and could also be collected afterwards and put to other uses (for instance for rinsing).

The third totally new model is a washing machine with an 'outboard' electric motor that can be plugged into a domestic power socket. This legendary Miele washing machine No. 50 is born.

-

1915

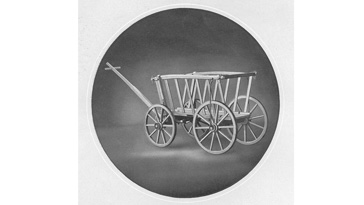

Born of necessity during the war, Miele adds hand-carts to its production programme. This product was such a success that it continues to be manufactured well into the Fifties.

-

1916

Miele is so convinced of the quality of its products even at that time that a 10-year warranty was available on request.

-

-

1920s

-

1920

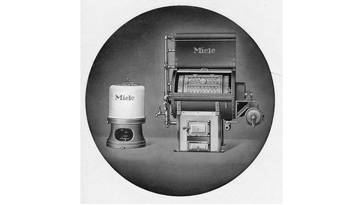

Milking is already highly mechanised. Small dairies, consisting of two to three pieces of equipment, process milk all the way through to making butter, all powered by a single motor.

-

1921

In the quest for a unique identity, Miele initially focuses its advertising efforts on conveying a clear profile of the brand with easily understood information.

-

1923

The Miele washing machine No. 50 with an attached electric motor as a direct drive is a significant improvement and results in most washing machines being equipped with wringers a short while later.

-

1924

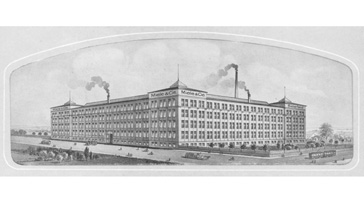

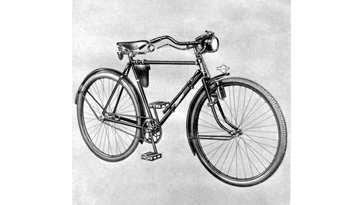

In 1924 it finally happens: The expanded Miele factory in Bielefeld begins the long-awaited production of bicycles.

-

1925

In 1925 Miele developed the first coal and gas-powered washing machines. With their large capacity, these machines are designed for in-house laundry facilities in hotels, restaurants, hospitals, etc. A large spin dryer to match is also delivered.

-

-

1930s

-

1930

Miele's cradle washer arrives on the scene in 1930, emulating the age-old principle of washing: dragging laundry to and fro under running water and beating it by hand. Operation of such a large machine requires the use of an electric motor.

-

1931

After the canister vacuum, Miele introduces its first vacuum cleaner in the "shape of a torpedo" with the Model L, a design that is still common today. New features, other than the shape of the floor head, include an attachment for gentle carpet cleaning, rubber bumpers and a Bakelite casing.

-

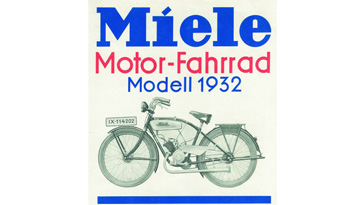

1932

Bicycles are fitted with a motor. Especially for older people as well as doctors, foresters, vicars and postmen in rural areas who travel widely, the Miele motorised bicycle brings welcome relief.

-

1935

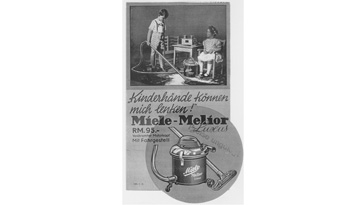

Vacuum cleaner sales now reach significant volumes. New, advanced models, simple operation and attractive prices, supported by intensive advertising, result in rapid sales growth.

-

1936

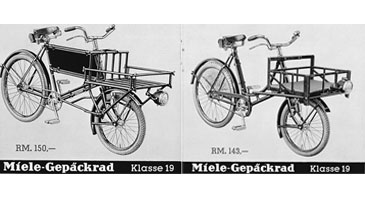

The development of bicycles continues at a rapid pace as well. A broad selection of models, ranging from light children's bikes to heavy cargo bikes offers the right solution for everyone.

-

-

1940s

-

1940

The production of household appliances has to be drastically restricted during the war years. Only approximately 22,000 washing machines - about 10,000 of them model No. 55 - could be manufactured in 1940.

-

1941

An important product in its day was the Miele bicycle for 'industrial service' - a bicycle built 'to withstand the roughest wear and tear'.

-

1943

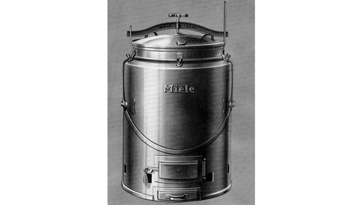

Stoves and feed cookers are urgently needed by the German food industry and Miele continues with their production.

-

1946

The first advertising brochures are printed again.

-

1947

The washing machine No. 122 KVJ is a new development with a lid-mounted agitator and a galvanised steel tub. The covered drive mechanism even features ball-bearings.

-

1949

Miele's 50th anniversary is celebrated on a modest scale. Instead, all employees receive a substantial gift of money, all Miele pensions are increased by 20% and a considerable amount is placed into the company's benevolent fund.

-

-

1950s

-

1952

In the Fifties, the washing machine leaves the outhouse or basement and moves into the home. This is accompanied by a change in shape as well - it becomes rectangular. This is what advertising says about washing machine No. 75s: An elegant, decorative exterior and an eye catcher in any kitchen or bathroom.

-

1953

The front loading washing machine No. 307 is one of the first to feature a 'porthole door'. For the first time machines are loaded from the front. The washing machine has a new appearance. It is the sign of the advent of automation in laundry care.

-

1954

The production of two-wheelers experiences peaks in the mid-Fifties. Mopeds, motorised bicycles and motorbikes are produced in ever increasing numbers. Miele advertising supports this trend with brochures providing in-depth information.

-

1955

President S, the new Miele vacuum cleaner, takes the growing trend towards more carpeting into account. Apart from a modern plastic casing, it features a new three-way nozzle. Thanks to a thread catcher and an adjustable bristle strip, it is suitable for use on all types of flooring.

-

1957

'Mum does it with Miele' – the new slogan that Miele uses toward the end of the Fifties in advertising vacuum cleaners. The result is spectacular: More than 100,000 vacuum cleaners are sold every year.

-

1958

In 1958 Miele begins a new chapter in the history of laundry care: The first electric tumble dryer for the home leaves the factory.

-

-

1960s

-

1960

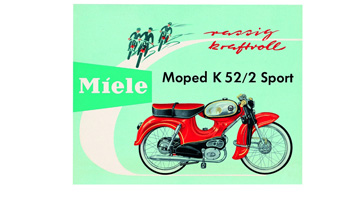

The production of two-wheelers slowly comes to a halt. The Miele moped K 52/2 Sport is the last new development in this area. The moped has a 47 ccm Fichtel & Sachs motor with pedal kickstarter and is equipped with a three speed transmission as a standard feature.

-

1961

Illustration of an advertising campaign for Miele vacuum cleaners.

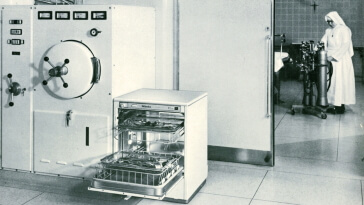

Miele is seeking its way into hospital markets with special washers. The first model is called G 15 OP Special for cleaning surgical instruments.

-

1963

A new dishwasher, the Miele G 45, is introduced to the market in 1963. Its exceptional features are: Enlarged capacity (12 standard place settings), can be built under thanks to standard kitchen dimensions, stainless steel wash cabinet, measured detergent dispenser.

-

1965

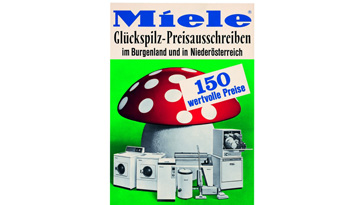

In 1965/66 Miele's very extensive production programme is publicised everywhere with large-scale regional advertising campaigns. For the 'lucky ones' promotion questions regarding the various appliances must be answered.

-

-

1970s

-

1970

The newly constructed central spare parts depot utilises the new technology of high-bay warehousing. About 35,000 storage locations with approximately 50,000 spare parts are managed via computer and loaded automatically by 18 service vehicles.

-

1971

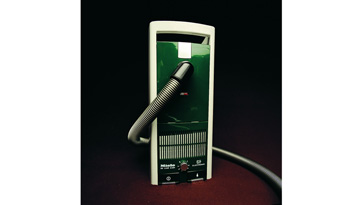

Vacuums get a facelift with models S 180, S 200 and S 204. High suction power of 1000 W as well as electronically controlled suction power are the most prominent features of the S 204 shown here.

-

1974

A new generation of built-in ranges enters the market along with the new kitchen generation from Miele's Warendorf plant. For the first time, the construction of appliances is precisely coordinated with the kitchen cabinetry and their design also complements the Miele kitchen splendidly.

-

1975

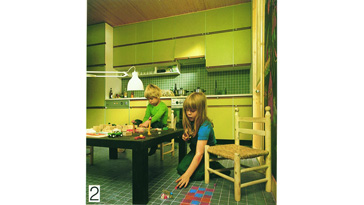

Kitchen production at the new Warendorf plant reaches full speed. The new cabinet fronts made from solid oak, stained in different colours, are a big attraction. But laminate fronts in modern colours are very popular as well.

-

1977

The microwave era begins. Miele's first product, the Model M 690, is initially a countertop unit that finds enough space anywhere thanks to its small dimensions. Later on, the appliance is also offered as a built-in option.

-

-

1980s

-

1981

A new generation of computerised washing machines and tumble dryers enters the market in 1981. The important benefits of the new Miele class are: 5 kg increased load capacity, faster spin speed and more environmental friendliness thanks to energy saving programmes.

A new style of advertising is introduced for Miele products: dialogue advertising.

-

1982

A new rotary ironer with roller speed control is introduced in 1982 with the model B 864 E.

-

1987

The new Miele museum is opened in 1987. As the oldest washing machine manufacturer in the Federal Republic of Germany Miele thereby offers, among others, a history lesson on the development of the washing machine that is unique worldwide.

'Top-level dishwashing' is the motto Miele uses to bring the first dishwasher with a cutlery tray to the market. Cutlery is washed thoroughly and gently on a third level above the two crockery baskets.

-

1989

New built-in ranges and ovens with integrated microwaves are now being shipped from the new factory in Oelde.

-

-

1990s

-

1993

A fully automatic distribution centre is opened at the Gütersloh plant. This new link in the supply chain, with a computer operated storage system for around 100,000 domestic appliances, ensures the targeted and efficient shipment of goods.

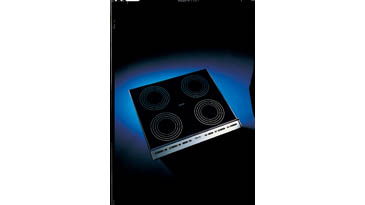

Cooking is now faster than ever before. Induction hobs ensure ultra-fast heating inside pots and pans, making for short cooking times and optimum power control.

-

1994

Miele also takes a giant step toward satisfying the desires of its customers by becoming involved in manufacturing fitted kitchens. All customers can now select the colour of their kitchens from a broad range of RAL colours. Customers can order their kitchens in exactly the colour they desire.

-

1996

The legendary Miele motorcar returns. Following a world-wide search, one of the first Miele motorcars, built in 1912, is located in Norway. After a mechanical overhaul, the car is the pride and joy of Miele's new museum.

'Update' is the buzzword around Miele's new automatic washing machines. The electronic controls are designed in such a way that programme configurations, taking changes in fabrics, detergents or fashions into account, can be adjusted even years after purchasing a machine.

-

-

2000s

-

2001

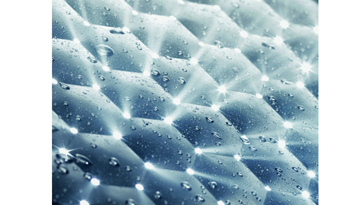

The Miele washing machine celebrates its 100th birthday and revolutionises laundry care with a world premiere: in the patented* Miele honeycomb drum, laundry glides gently on a film of water. *European patent: EP 0 935 687

-

2004

At the TexCare trade show, Miele presents the new generation of washer-extractors and tumble dryers with the freely programmable Profitronic M controls. The machines with load capacities of 10 to 20 kg are available in a variety of versions. The washer-extractors and tumble dryers with the well-known shield design are awarded various design prizes. WfK* confirms exceptionally gentle laundry care. Particularly the woollens programme in combination with the honeycomb drum is as gentle as washing by hand. *WfK – Krefeld Laundry Research Institute.

-

2004-2009

The perfect vacuum cleaner for every household: Whether particularly light and manoeuvrable, equipped with convenient features, powerful in operation or even cordless - each model series has its own charm.

-

2007

The detergents and care products from Miele create a system solution that, together with our high-quality domestic appliances, guarantees perfect results every time. The cleaning products and detergents are perfectly matched with the respective appliances, ensuring outstanding results.

Miele presents the new built-in ranges and ovens with Moisture Plus. A combination of fan heaters and moisture keeps roasts succulent and bakes bread with a fine crust. Additionally, all new Generation 5000 built-in kitchen appliances complement each other perfectly in terms of design and ease of use.

-

2009

For the most discerning of customers, Miele develops the FIRE and ICE series – with surface finishes in titanium or aluminium, trimmed with chrome or gold plating. Standard design worlds in stainless steel, Brilliant White Plus and black also remain convincing and attractive options.

-

-

2010s

-

2010

The more economical EcoLine washing machine models are characterised by special eco-friendly wash programmes. At the same time, they have the globally unique Eco Feedback function through which consumption values can be called up any time. In this way, environmentally conscious consumers can have a direct influence on energy consumption.

To the delight of those who love perfect coffee, exquisite design and superior ease of use, Miele introduces its first fully automatic countertop coffee makers. Thanks to their compact design, there is ample space for them on every worktop. On the inside, their technology corresponds to that of the proven built-in units.

With Miele's 'InfoControl Plus' all household appliances are conveniently in view at the same time. Using wireless LAN technology, users are able to check on the status of appliances throughout the home by calling up the selected programme, the operating mode or the remaining cycle time. An additional new feature is that appliances can now also be remotely controlled: Switching them on and off from every location in the home is no problem. Functions with safety relevance are excluded, of course. Consequently, it is not possible to turn on the hob or turn off the refrigerator via your mobile device.

-

2011

For the first time in its company history, Miele presents a steam ironing system with an 'active' ironing table. The patented 1-2-Lift System, which allows the ironing table to fold away effortlessly, delights ironing beginners and professionals as much as the many Miele-exclusive features and highlights.

The Miele cutlery tray celebrates its 25th anniversary. The patented, 3D cutlery tray can be adjusted in height, width and depth and offers numerous ways of arranging even large, awkward cutlery items.

-

2012

With the new FlexTouch induction hob from Miele, cookware can be placed anywhere on the ceramic screen. The actual position of the pots will be indicated 1:1 in the display. This makes operation easy and intuitive.

As successor to the popular and award-winning S5, the S8 comes under starters' orders. The new premium class of vacuum cleaners offers better cleaning performance, more user convenience and improved energy efficiency – and a whole host of patents and unique features. Even before its launch, the top-of-the-range model receives the coveted 'red dot design award'.

-

2013

'PureLine' and 'ContourLine' are the names of the two design lines which add a wide range of colours and materials to the new Generation 6000 built-in appliances and give it their own unique profile. New front colours and handles, innovative displays and user interfaces make for customised design and perfect integration with interior designs and furnishings.

All Miele washing machines from the new W1 generation are characterised by an easily surveyed, simple and intuitive user interface. At the same time, they sport new features which simplify laundry care and allow programmes to be tailored to suit individual needs.

Convenient, economical, environmentally friendly and in a uniform design, the new T1 tumble dryers are a perfect match for their washing machine siblings. All models feature heat-pump technology and are at least A+ rated for energy efficiency, if not better.

With its fully integrated dishwashers from the Generation 6000 series, Miele launches the innovative Knock2open feature: Tapping twice on the machine front opens the dishwasher door which is otherwise completely concealed behind a handleless cabinetry front.

-

2014

Miele is awarded one of Europe's most coveted sustainability prizes for its far-sighted and long-term corporate policy. Miele won the prize in the 'Large companies' category. The jury honoured in particular the company's comprehensive sustainability strategy and the durability of its products.

The Scout RX1 marks the advent of Miele's first robovac. This new entry to the product range convinces consumers the world over with its navigation system (SmartNavigation), good cleaning performance and the exceptional charge and longevity of its lithium ion rechargeable batteries.

Miele's domestic appliance app is available for the Qivicon Home Base. Miele is a founding partner in the Qivicon connectivity platform which unites brands across industry by offering smart-home applications providing a common technological basis. Owners of Miele domestic appliances are able to activate an application on their Qivicon portal enabling the status of appliances to be queried and machines to be controlled from anywhere.

Miele celebrates 90 years of commercial laundry technology: Since 1924, Miele has been developing and manufacturing commercial machines for laundries. Today, Miele offers its commercial clients a coordinated range of washer-extractors, tumble dryers and flatwork ironers facilitating gentle laundry care, cost-effective machine operation and streamlined workflow processes. Twenty-first century innovations still emanate from the same traditions as the very first machines.

-

2015

The Gütersloh high-bay distribution centre for washing machines, tumble dryers, dishwashers and ovens, inaugurated 20 years previously, was at the time as one of the highest-capacity installations of its kind. Due to unit sales growth, the hub was recently often stretched to its capacity limits. This was exacerbated by an increasing centralisation of logistics processes. As a result, Miele has now expanded the capacity of its logistics centre by 75%. The additional storage space measures 77 x 62 m and the building has a height of 36 m. In total, the warehouse holds approximately 188,000 appliances. The same technology is used in the extension as in the original centre for the distribution of finished goods, which first went online in 1994.

Two new milestones for Miele in Bielefeld: 88 years ago, production first started here – and this year the 50-millionth vacuum cleaner in the company's history left the factory gates.

American flair on the European domestic appliance market: With its range cookers, Miele presents XXL models developed for the North American market which are now adding new impetus to markets in Europe and proving a source of great enthusiasm.

No more risk of burnt food and no need to constantly adjust power combined with the best possible results: The new induction hobs bearing the TempControl logo make frying in particular a considerably simpler and more leisurely affair. The correct temperature is maintained at all times by sensors embedded in the ceramic screen. TempControl works together with all pots and pans suitable for induction.

-

2016

The new G 6000 EcoFlex dishwashers require less than an hour for an A-rated wash cycle, as confirmed by Germany's TÜV material testers – a feat accomplished only by Miele. In the Eco programme, the dishwashers even surpass the required value for a top-class A+++ energy-efficient programme by up to 20%. Thanks to its newly designed baskets, Miele is also further increasing its lead in terms of flexibility and loading convenience. And: numerous EcoFlex dishwashers are now WLAN-enabled.

Where kitchens and living rooms merge, a clear design statement is needed: Preferably puristic, straight-laced and handleless as prominent individual elements would otherwise cloud the overall impression. Miele is catering for this trend with its new ArtLine series of built-in appliances. The entire collection dispenses with handles, blends in seamlessly with flush furniture fronts and interprets the concept of full appliance integration in a whole new way – optionally in Miele’s new graphite grey, in brilliant white or in obsidian black.

2016 Miele's Bielefeld plant celebrates the 100th anniversary of its founding: The plant was set up in 1916 by the company founders Carl Miele and Reinhard Zinkann as a branch in Gütersloh's neighbouring town. Covering around 134,000 m², this is now the second-largest factory within the Miele Group. It has three areas of focus: Domestic dishwashers, vacuum cleaners and Miele Professional. The bulk of investments over recent years has gone into new-build premises housing an innovation centre for commercial cleaning systems.

Excellent cleaning results and extremely convenient and hygienic emptying of the dust container – these are the more prominent benefits of the Blizzard CX1. On top of all this, the first bagless vacuum cleaner from the Miele company protects the user against the exposure to noise levels which are so typical of this product category. And add to this Miele's proverbial quality and many a clever detail which can be found nowhere else.

The 1 millionth steam oven is produced at Miele's Bünde plant. This number illustrates a real success story as only 20 years previously domestic steam ovens were rarities in the kitchen. It was Miele that helped this product to break through, and Miele still offers the broadest assortment of steam ovens and combination products today. These models are produced in Bünde using modern production methods and communication technologies.

-

2017

On account of continued growth in product variants and sales figures, Miele once again expands its logistics operations in Gütersloh. Following on the heels of the enlargement of the high-bay storage warehouse in 2015, the entirely new central spares store (ZEL) on the other side of the railway lines which skirt the factory site assumes regular operation. To ensure a fast supply of spares and accessories to dealers, consumers and sales subsidiaries, Miele had previously rented external storage space to boost the capacity of the old warehouse for spare parts. This compromise, however, soon found itself stretched to the limits. Thanks to the new Central Spares, up to 8,000 parcels a day can now be expedited, equating to an 80% increase. The new premises house fast and moderately fast movers, items frequently ordered. Unpackaged spares and slow movers are stored in the old spares store.

With the new dialog oven from Miele a new technology is being deployed for the very first time in which electromagnetic waves respond to the texture of food in an intelligent manner. Meat, for example, is cooked more uniformly, retaining its juices. Fish and vegetables keep their fine structure and dough rises significantly better. Various fresh ingredients for a complete meal can be placed together on an oven tray and are all finished to perfection at exactly the same time – and up to 70% faster than using conventional cooking methods.

-

2018

Miele's day-care centre for employees' toddlers represents a milestone in striking a balance between family and career. IdeenReich commenced operations in the summer of 2018. Miele Executive Director Olaf Bartsch handed over the symbolic key to the new facilities to Britta Hüfing from pme Family Services, the service provider.

At the last IFA exhibition, Miele presented its new dialog oven. Now, the Miele startup called MChef is delivering the matching haute cuisine to customers' homes with its sophisticated three-course menus. The ingredients are presented on elegant porcelain ready to be cooked to perfection in a dialog oven. On request, orders can include a suitable wine or Champagne, naturally at the correct temperature for serving. The target audience for the new gourmet service are owners of a dialog oven who wish to dine as if in their favourite restaurant in the comfort of their own home.

The new dishwasher G 7000 is promising hitherto untold dishwashing freedom – thanks to AutoDos and its integrated PowerDisk. This unique system dispenses detergent automatically and uses powder granulate specially designed for the purpose. Furthermore, the new dishwashers can be controlled by an app and programmed from a mobile device. All that remains for the user to do is to load and unload the machine and, occasionally, to replace the PowerDisk. Everything else can be left to the machine. Also, baskets and the cutlery tray have undergone further optimisation.

-

2019

With its Generation 7000, Miele is renewing its entire product range of built-in kitchen appliances, from ovens and hob units to steam ovens, coffee machines through to dishwashers. Aesthetically, Generation 7000 with its four new design lines offers inspiration for virtually every interior design style. A further benefit is the ease with which the new Miele appliances help their users to attain culinary excellence. There are also smart assistants on board, including a camera in the oven or a system to prevent roasts from becoming too dry. With nearly 3,000 model versions worldwide, the Generation 7000 of built-in appliances also represents the largest product launch in the company's history to date.

What began 90 years ago was to become a most extraordinarily arresting success story – marked by impressive technical milestones and millions of satisfied customers. The most recently produced 20-millionth dishwasher is a G 7310 SC CLST. Thanks to AutoDos with integrated PowerDisk, this model to celebrate the anniversary dispenses automatically. It was not, though, given a place of honour in the company as it was presented to the owner of Germany's oldest, still functioning Miele dishwasher.

Miele is introducing its first rechargeable handstick in the form of the Triflex HX1. It excels in terms of its excellent suction power, a battery running time of up to 120 minutes and, in particular, its exceptional flexibility as embodied in the 3-in-1 concept: The PowerUnit, consisting of motor, rechargeable battery and dust box, can be converted in a matter of seconds to adapt to the job in hand – for example vacuuming under furniture, cleaning larger surfaces or, in solo mode, cleaning tables or upholstery.

Miele takes over the vertical farming specialist Agrilution. Vertical farming is a term used by futurologists to denote multi-level greenhouses providing a local and space-saving supply of fresh produce, for example in urban conurbations. With the Plantcube from Agrilution, this revolutionary concept is now finding its way into private homes. Fully automatic, small-scale vertical farms are no larger than a standard refrigerator, offer perfect growing conditions combined with minimal effort – and are a design highlight in any kitchen or living room.

-

-

2020er

-

2021

The family-owned companies Miele and Steelco have joined forces: Both companies are among the world's leading manufacturers of washer-disinfectors and sterilizers for hospitals, medical and dental practices and laboratories. The Italian medical technology manufacturer Steelco is also highly represented in the special segment - new to Miele - of reprocessing components used in pharmaceutical production. In April 2021, Miele acquired the majority of Steelco shares. The overarching goal is to provide customers with an even more powerful product portfolio and the best possible service, both before and after the purchase.

For many years, Miele Professional has stood for dependable hygiene in the medical sector as well as in hotels and restaurants. This expertise in the field of hygiene is now being transferred to air purification – in the form of Miele AirControl, available in three sizes and manufactured at Miele’s own Lehrte production plant. Five-fold filtration removes 99.995% of all air-borne particulates, viruses, bacteria and fungi. After each operation, pathogens are thermally deactivated by Miele ThermoControl. With a capacity of up to 3000 m³/h (depending on the model), these models are able to replace and filter the entire air in a room six times in a single hour.

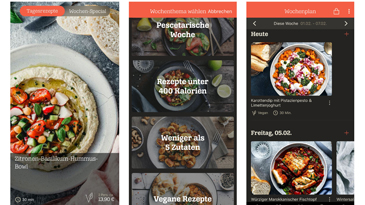

A fresh, healthy and sustainable cuisine is increasingly becoming an integral part of daily life for many people – with recipe ideas nowadays found above all online. In this respect, the KptnCook app provided by the eponymous Berlin startup counts among the fastest-growing offerings in the German-speaking world – with Miele holding a stake in the company since 2018. In February 2021, the Gütersloh domestic appliance company increased its share in KptnCook to over 50%. The common goal is to further fuel the growth of this multiple award-winning app in Germany, Austria, Switzerland and beyond.

In March 2021, Otto Wilde Grillers and Miele joined forces to address the high-potential field of outdoor cooking: Otto Wilde shares its expertise in manufacturing high-end grills and accessories. Miele, for its part, brings many years of know-how in the development, production, connectivity and marketing of premium built-in appliances worldwide to the table.

The battle to curb climate change is perhaps one of the biggest challenges of our day and age. As a consequence, industry is also increasingly under pressure to make its own sizeable contribution towards a solution. Miele takes on its responsibilities: From 2021 onwards, the Gütersloh company will be CO2 neutral at all its locations. This refers to greenhouse gas emissions resulting from its own production processes (Scope 1) as well as those in power generation at its energy suppliers (Scope 2). The objective is to reduce calculatory CO2 emissions by 50% by 2030 compared with 2019.

Since December 2021, Miele invites customers to experience its brand live with all their senses in a top location in Düsseldorf. Following the Miele Experience Centers at the headquarters in Gütersloh and in Berlin (Unter den Linden at the corner to Friedrichstraße), Düsseldorf is the company's third location in Germany. At the Düsseldorf Brand Store, Miele's entire range of domestic appliances is on sale, as well as popular accessories such as roasters and vacuum bags and the Miele care products.

-

2022

At the end of 2021 Miele took over the family-owned Eurofilters company, which stands for highly effective solutions based on random-spun fibres, such as materials for face masks and dust bags. The two companies have a long-standing and successful business relationship as Eurofilters already produces a large proportion of the dust bags available from Miele.

The new generation of Miele's handstick, Triflex HX2, offers not only flexibility thanks to the patented 3-in-1 design, but also 60% more suction power than its forerunner - making it Miele's most powerful vacuum cleaner. This is due to the new, powerful Digital Efficiency motor, in combination with the proven monocyclone design (Vortex technology) and the powerful Multi Floor XXL electric brush. It detects floor coverings and reduces the rotation speed on hard floors, thereby saving energy and extending the battery life. The redesigned filter and dust container with ComfortClean makes everyday life with the HX2 much easier.

Rebecca Steinhage joined the Executive Board of the Miele Group on July 1, 2022. The former Senior Vice President Human Resources has been with Miele since 2019. In her role as Executive Officer, she will take over the newly created area Human Resources & Corporate Affairs, which, in addition to Human Resources, includes the departments of Sustainability, Communications and Internal Audit. The photo shows the now six-person Executive Board with (from left) Dr. Markus Miele (Executive Director and Co-Proprietor), Dr. Stefan Breit (Technology), Dr. Axel Kniehl (Marketing & Sales), Rebecca Steinhage, Dr. Reinhard Zinkann (Executive Director and Co-Proprietor) and Olaf Bartsch (Finance & Administration).

The Miele plant in Bürmoos underwent a reorganization to mark its 60th anniversary. In Bürmoos, high-quality stainless steel components are manufactured for almost all appliance factories of the Miele Group as well as for the Italian subsidiary Steelco. In addition, Miele's new subsidiary Otto Wilde Grillers now has its most established product series produced in Bürmoos. Miele made investments in a new cutting center with a fully automated high-bay warehouse and laser machining as well as in the most modern manufacturing technology for surface finishing.

-